November 18thWing-fi technologyI'm inHumanoid RobotField, launch the first human robot under the flag on November 17th."Hung”.

"Hong Chong" carries an autonomous R & D based on MTM technology YiBrain SystemThis system, which can be integrated in depth with the bottom control system (intellectual small brain), transforms the reconfigured mission sequence into a joint motion command, a power-crack control signal and a mobile navigation command。

The robot did not use double-footed walking, but rather carried lift-down + wheeled composite control structures, developed its own modular four-way, four-way to-drive chassis, and mounted a real-time response system with multiple motion models"hong" enables the full-directional movement of ackerman's direction and rotation to support 2m/s movement and 360o62cm narrow space travel through。

through integrated 0.4m/s lifts"Hong Chong" has achieved a high height, up to 0.5 m for a "three-dimensional space operation" combined with a surface slide, declared to cover high demand for industrial scenes above 95%。

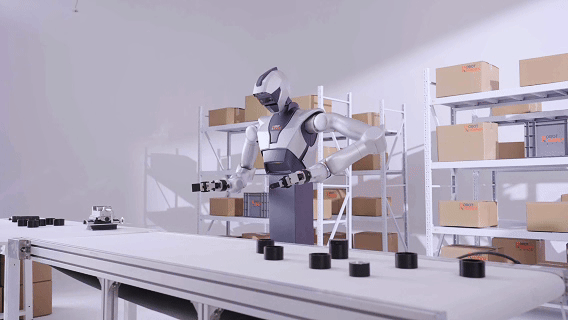

In order to achieve a fine assembly, the "Hong Cong" carries an autonomous development of a biomimic arm, which uses 313 structural configurations, with three, one, three degrees of freedom for shoulder, elbow and wristTotal single-armed 7 degrees of freedomRegraving human arms。

biomimicry mechanical arm stretch 0.6 m, peak load 5kg, end-end repeat position precision 0.05 mm to complete multiple smart grabs and fine assembly。

In addition, the skeletal skeletal skeletal skeletal model simulates the one-way mobility of human wrists, enabling them to conduct complex actions such as twisting, pulling, pressing, etc. at any angleTo achieve 360° rotation and multi-angle attitude adjustmentwith a maximum joint speed of 275°/s。

The smart wrists of the Hung fit the standard electric wrench, vacuum straws, claws, etcToggle the type of job by quickly changing hands - From screws to plug-in cables, from tagging to capturing parts, a device can cover multiple job requirements without having to be equipped for a single mission. The following illustrations are attached:

According to Wing Fifi technology, "Hong Dynasty" has the capacity to fit the whole scene without a fixed jobNo reliance on pre-set orbits or fixed deployment points, with flexibility to adjust operational positions to real-time requirements of production linesI don't know. Whether the product line layout is temporarily optimized or new products need to be re-engineered, it can respond quickly - it does not take much time to re-engineer deployment, it does not have to cover the high costs associated with the relocation of fixed equipment, it integrates into the dynamically changing production environment, and it avoids the waste of resources for equipment temporarily out of the core process due to a change of scene, and it matches the flexible demand for HF replacement。

In small batches, multi-product production scenarios, it can rapidly switch the type of operation according to mission directivesNo additional specialized equipment requiredThe problem of low utilization of equipment under the “one-size-fits-all” model was avoided, as was the ability to connect different production chains to meet the core requirements of diversified production。

For short-term orders or temporary production needsThe "Hong Cong" programme has achieved quick start-up in the form of "go-and-go" supplementary labourNo enterprise needs to be equipped with a full set of specialized automation equipment. The design objective is to achieve seamless synergy with the existing production systems of the enterprise, without the need for large-scale retrofitting of existing production lines, and is expected to effectively reduce the cost of idle equipment and rigid inputs associated with short-term assignments. At the same time, it is expected to be adapted to different batches and different types of production tasks, based on generic attributes, to provide more flexible cost-control options for enterprises to cope with market fluctuations。